Overview

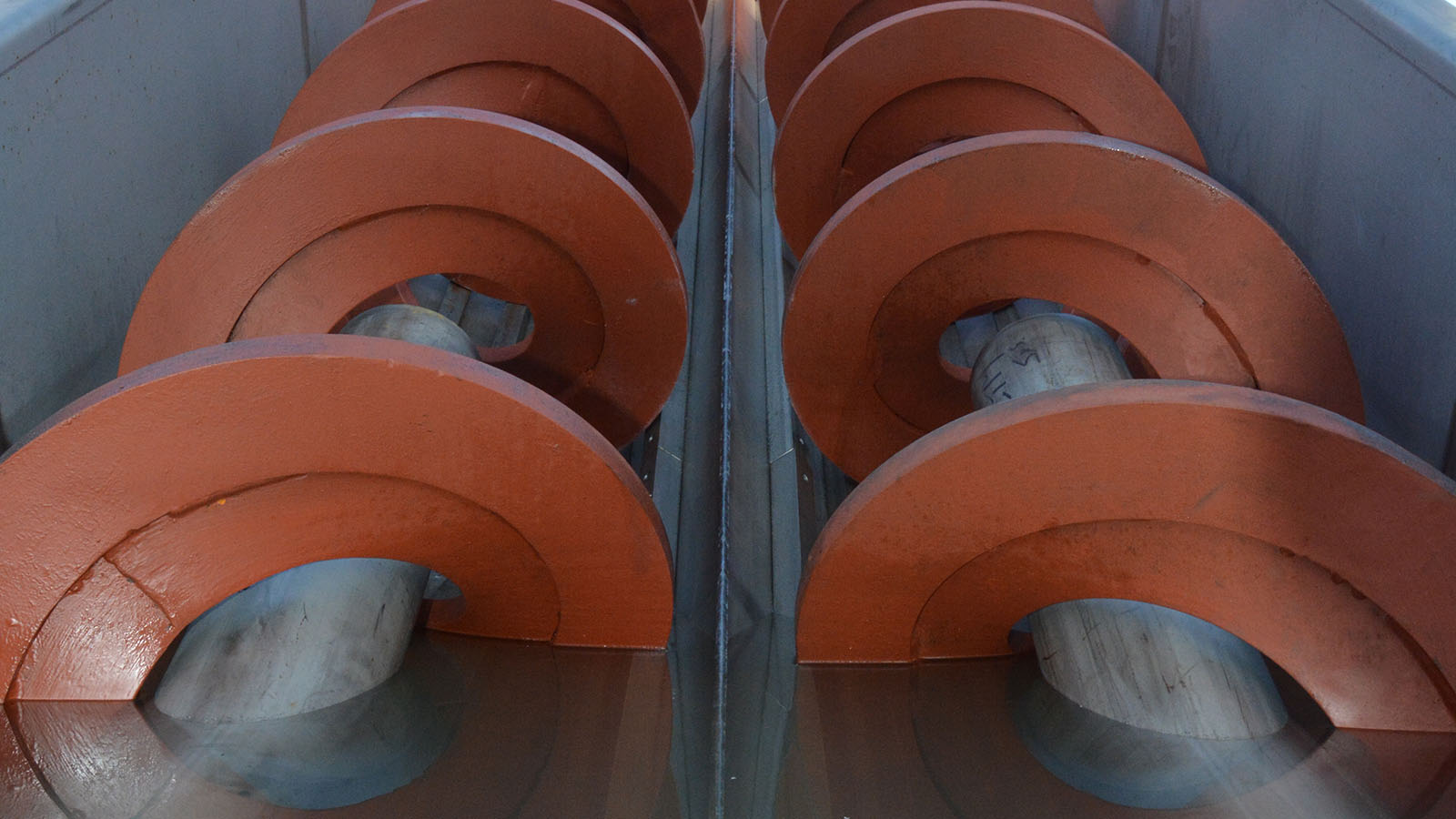

Parnaby Cyclones manufacture a wide range of dewatering screws for a wide range of applications. These are bespoke designed and robustly manufactured to suit our customers specific, often unique requirements.

Our dewatering screws can often be referred to in the marketplace as screw separators due to the process of dewatering as the material travels up the screw.

How do de-watering screws work?

The material is fed directly into the separation bath of the de-watering screw where the heavier material sinks and is screwed out via the screw auger. As the material travels upwards on the screw, gravity and the unique design both ensure optimal dewatering of the materials

Technical Details

| Screw Separator Range | Throughput TPH | Water Requirement | Overall Dimensions | Equipment Weight |

|---|---|---|---|---|

| MK3 | 5-7 TPH | 40m³ initial fill requirement | H:7200mm W:4100mm L:15000mm |

12 Tonnes |

FAQs

A dewatering screw is used to separate liquids from solids in the recycling industry. It is often referred to as a screw separator due to the process of dewatering as the material travels up the screw.

It works by using a rotating screw to transport the material through a cylindrical screen. As the material moves up the screw, the liquid is separated from the solids, and the solids are compacted and dewatered.

A variety of materials, including food waste, industrial waste, paper and pulp, and municipal sludge.

The benefits of using a dewatering screw in the recycling industry include reduced waste volume, increased efficiency, and reduced transportation costs. The dewatered solids can be used for composting or landfill, while the separated liquid can be treated or reused.

Regular maintenance is required for a dewatering screw, including cleaning and inspecting the screw and screen, checking for wear and tear, and replacing any damaged components. It is important to follow the manufacturer's guidelines for maintenance and to schedule regular servicing to ensure optimal performance.

Yes, it can be customised for specific applications, depending on the material being processed and the desired output. Customisation options include screen size, screw diameter, and material of construction.

The expected lifespan of a dewatering screw depends on factors such as the frequency of use, the material being processed, and the maintenance schedule. With proper maintenance, a dewatering screw can last for many years.

Make an enquiry

Ian Parnaby

Projects Manager